Introduction

In the world of naval architecture, Computational Fluid Dynamics (CFD) has revolutionized how we design and analyze ships. CFD allows engineers to simulate fluid flow around ship hulls, providing valuable insights into performance, efficiency, and stability. In this article, we’ll explore the role of CFD in modern ship design and how it benefits the marine industry.

What is Computational Fluid Dynamics (CFD)?

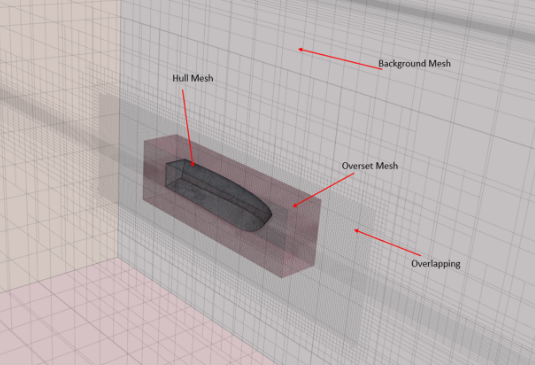

CFD is a branch of fluid mechanics that uses numerical analysis and algorithms to solve and analyze problems involving fluid flows. By applying CFD in ship design, naval architects can predict how water and air interact with the vessel, leading to optimized designs and improved performance.

Benefits of Using CFD in Ship Design

- Accurate Predictions:

- CFD simulations provide detailed and accurate predictions of fluid behavior around a ship’s hull.

- This accuracy helps in identifying potential issues and areas for improvement early in the design process.

- Cost-Effective:

- Traditional physical testing, such as towing tank tests, can be expensive and time-consuming.

- CFD reduces the need for extensive physical testing, saving both time and money.

- Design Optimization:

- CFD allows for the exploration of various design alternatives quickly and efficiently.

- Designers can test different hull shapes, appendages, and configurations to find the most optimized design.

- Performance Improvement:

- By analyzing factors such as resistance, propulsion, and seakeeping, CFD helps in enhancing overall vessel performance.

- Optimized designs lead to reduced fuel consumption and improved speed.

Applications of CFD in Ship Design

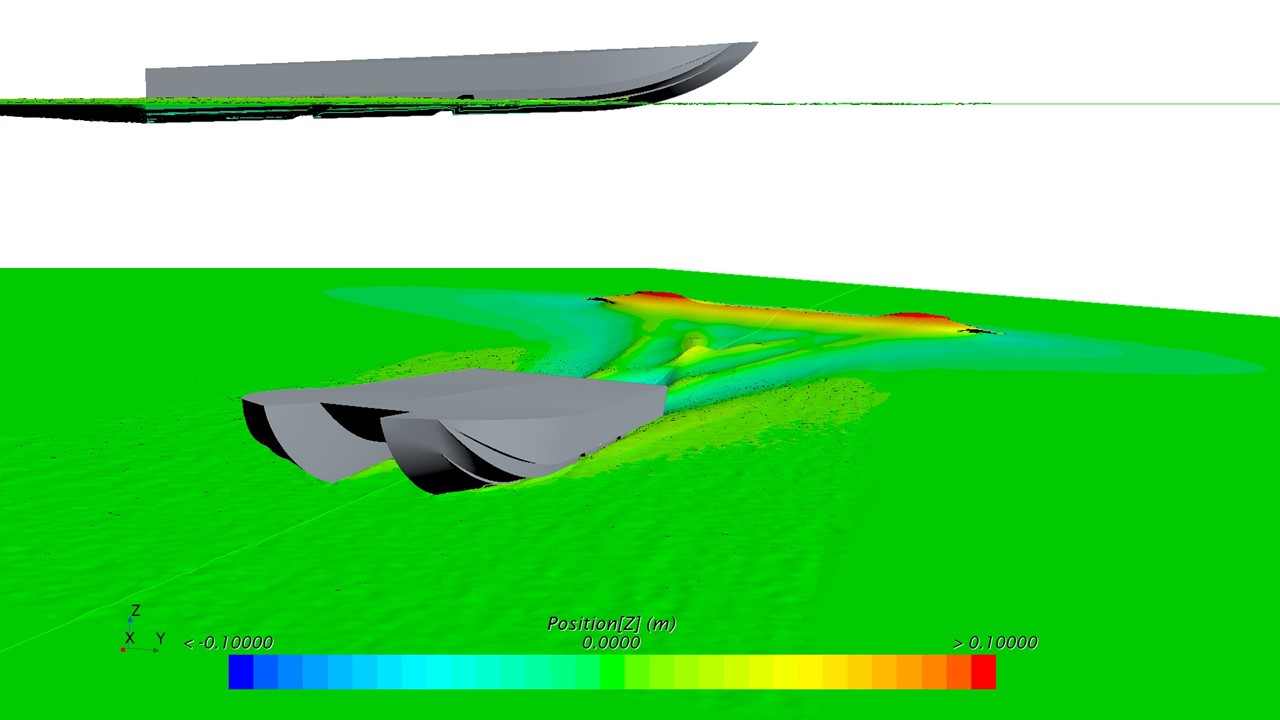

- Hull Form Optimization:

- CFD is used to analyze and optimize the hull shape to reduce resistance and improve fuel efficiency.

- Streamlined hull designs lead to better performance and lower operational costs.

- Propeller Design:

- Propeller performance is critical for efficient ship propulsion. CFD helps in designing propellers that maximize thrust and minimize cavitation.

- This results in smoother and more efficient propulsion systems.

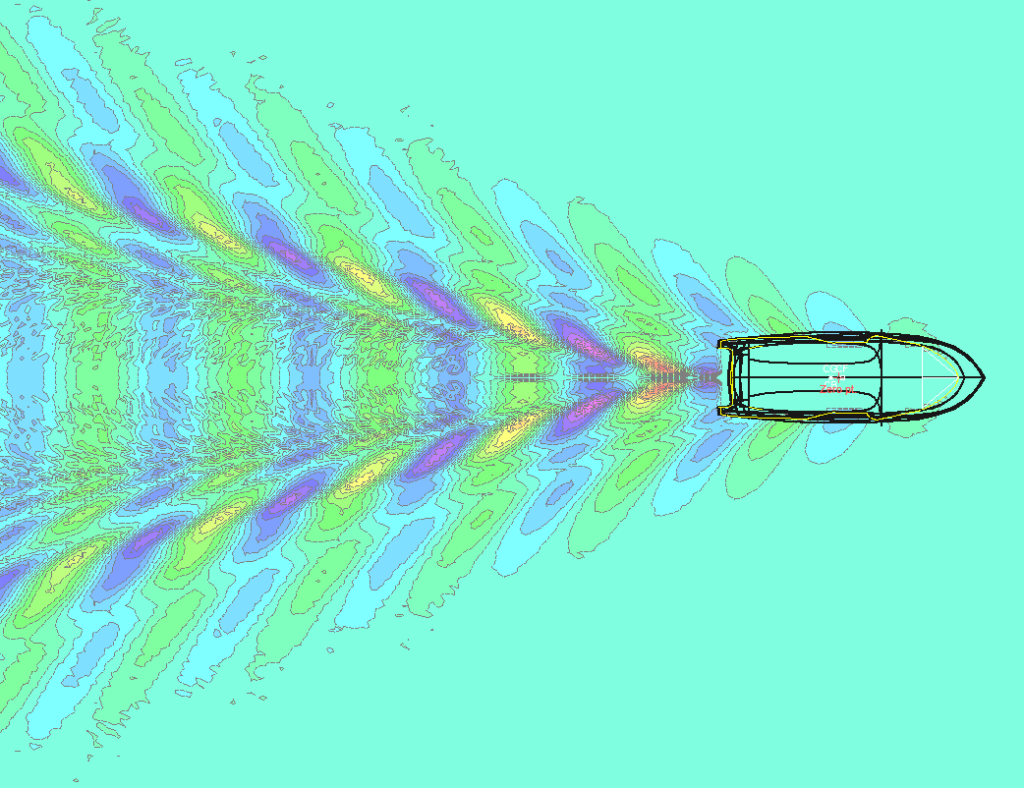

- Seakeeping Analysis:

- Seakeeping refers to a vessel’s behavior in waves. CFD simulations help in predicting and improving a ship’s seakeeping performance.

- Enhanced seakeeping ensures passenger comfort and operational safety in various sea conditions.

- Flow Analysis Around Appendages:

- Appendages such as rudders, bilge keels, and stabilizers affect a ship’s performance. CFD helps in analyzing and optimizing the flow around these appendages.

- Properly designed appendages improve maneuverability and stability.

Conclusion

The integration of Computational Fluid Dynamics (CFD) in ship design has transformed the marine industry. By providing accurate predictions and enabling design optimization, CFD helps in creating efficient, safe, and high-performing vessels. At Marine Design Consultancy, we leverage advanced CFD tools and techniques to deliver superior ship designs. Contact us today to learn more about how our CFD expertise can benefit your projects.